What Makes Outdoor Gear Work: The Hidden Science Inside Your Favorite Jacket

2026-02-13 16:31

Pull on a trail running shirt or zip up a rain jacket, and you probably don’t think about the engineering behind it. But modern outdoor apparel is a quiet marvel. It has to keep you cool when you’re climbing, dry when you’re caught in a downpour, and fresh after three days in the backcountry—all without weighing you down or falling apart. That kind of versatility doesn’t happen by accident. It takes carefully engineered fibers, smart construction, and increasingly, a genuine commitment to making it all without trashing the planet.

Moisture-Wicking and Quick-Dry: Keeping Sweat from Sticking Around

When you're moving fast, your body pumps out sweat. A cotton T‑shirt soaks it up, turns heavy, and stays wet—which is exactly what you don't want when the temperature drops or the wind picks up. Moisture-wicking fabrics flip that script. Instead of absorbing water into the fiber core, they use capillary action to pull liquid across the surface and spread it thin, where it evaporates faster.

Engineers achieve this in a few ways. Some polyester fibers are extruded with non-round cross‑sections—think four-channel or trilobal shapes—that create microscopic grooves. Those grooves act like tiny gutters, drawing sweat away from the skin. Other fabrics use a double‑face knit: one side hydrophilic (water‑loving) against your skin, the other side hydrophobic (water‑hating) facing outward, so moisture moves in one direction only and won't creep back in. The real test of these fabrics isn't just how fast they move sweat, but how quickly they dry once they're saturated. That's measured in labs with controlled drip tests and drying plates, and it's the difference between shivering at camp and staying comfortable.

Waterproof and Breathable: The Art of Keeping Rain Out Without Trapping Heat In

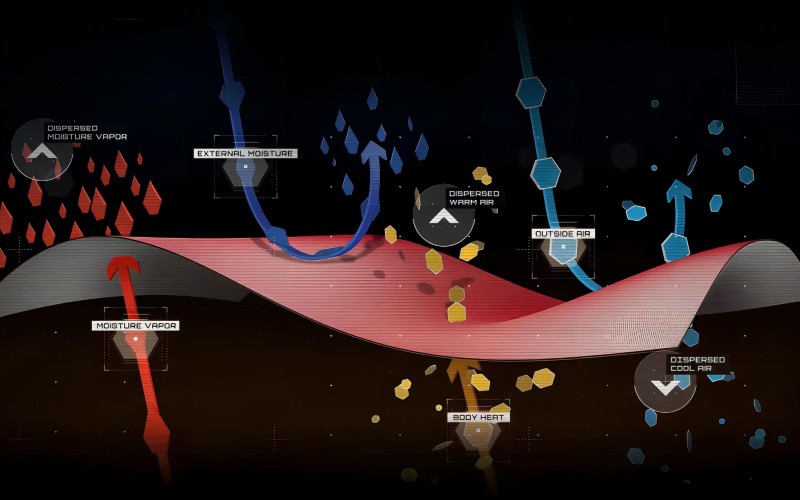

Waterproofing is straightforward: you can coat fabric with rubber and call it done. But then you'll sweat like you're in a sauna. The real challenge is keeping rain out while letting water vapor—your body's escaping heat and moisture—get through. That's where waterproof/breathable membranes come in.

The best‑known solution is the microporous membrane. It's a thin film riddled with pores so tiny that liquid water droplets can't pass through, but individual water vapor molecules can. Think of it like a chain‑link fence that stops basketballs but lets marbles roll right through. Other membranes work without pores at all; they're hydrophilic solids that actually absorb moisture molecules and shuttle them along polymer chains until they're released on the outside. Both approaches work, but they breathe differently.

Then there's the face fabric. It needs a durable water repellent (DWR) finish to keep the outer layer from wetting out, because if that fabric saturates, the membrane can’t breathe. For years, DWRs relied on long‑chain fluorocarbons—PFAS—that worked brilliantly but never broke down in the environment. Today, the outdoor industry is in the middle of a massive shift toward PFAS‑free alternatives. They’re not always quite as effective, but they’re getting better, and they don’t persist in rivers and bloodstreams for generations.

Antimicrobial and Odor Control: Why Your Shirt Smells After a Long Day

Sweat itself doesn’t stink. What you’re smelling is bacteria—specifically, the metabolic waste of microbes that thrive in warm, damp fabric. Antimicrobial treatments don’t just mask odors; they stop the microbes from multiplying in the first place.

The most common approach is silver. Silver ions are incorporated into the fiber or applied as a finish, and they punch holes in bacterial cell walls or interfere with their enzymes. It’s effective and durable, but it comes with environmental trade‑offs. Zinc‑based technologies are gaining ground as a lower‑impact alternative. Meanwhile, a quieter shift is happening toward bio‑based solutions: chitosan, derived from crustacean shells, and certain plant polyphenols can disrupt bacterial growth without introducing heavy metals. These aren’t yet mainstream, but they point toward a future where antimicrobial gear is both high‑performance and compostable.

What's often overlooked is that antimicrobial treatments also extend garment life. By preventing microbial degradation of fibers—especially in items like shoe liners or insulated jackets that don’t get washed often—they keep gear functional longer. And that, in itself, is a sustainability win.

Where Performance Meets Responsibility

For years, outdoor enthusiasts accepted a quiet bargain: high performance came at an environmental cost. That assumption is crumbling. Recycled polyester from plastic bottles is now common in trailwear. Nylon can be reclaimed from fishing nets and industrial waste, then respun into fabric as strong as virgin material. Solution dyeing, which adds pigment to molten polymer before fibers are formed, slashes water use by as much as 80 percent and eliminates dyehouse effluent entirely. Mono‑material construction—making a whole jacket from a single fiber type—is gaining traction because it simplifies recycling at end of life.

CJTI has been at this for more than sixty years. As a vertically integrated manufacturer, we don’t just buy yarn and turn it into cloth; we engineer the yarn itself, design the fabric structure, and refine the finishes. That deep reach across the production chain lets us solve problems that would otherwise fall through the cracks between supplier and mill. It also lets us do it responsibly. Our production model is built around resource efficiency, chemical stewardship, and durability—because the most sustainable garment is the one that doesn’t need replacing. Whether it’s a moisture‑wicking base layer, a breathable rain shell, or an antimicrobial lining, we build fabric that works for the athlete and for the planet.