What Are Functional Fabrics: Revolutionizing Safety and Performance

2025-11-13 22:51

In an era where technology and textile science converge, functional fabrics are redefining the way we think about clothing and materials. These advanced textiles go beyond basic covering and aesthetics to offer specific protective and performance-enhancing properties tailored to diverse needs. From workplaces with hazardous conditions to everyday activewear, functional fabrics are becoming integral to modern life.

Understanding Functional Fabrics

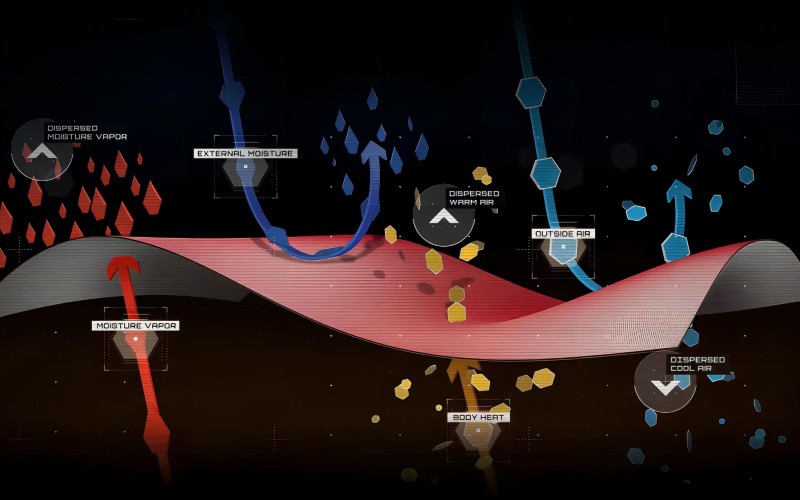

Functional fabrics, also known as technical textiles, are engineered materials designed with specific purposes beyond traditional clothing functions. These fabrics undergo specialized treatments or incorporate advanced fibers to achieve properties like flame resistance, antistatic capabilities, moisture management, temperature regulation, and UV protection.

The global functional fabric market is experiencing significant growth, driven by increasing safety regulations and technological advancements. These fabrics are particularly essential in protective workwear for industries such as metallurgy, mining, forestry, chemical, and petroleum, where worker safety is paramount.

Key Types of Functional Fabrics

1. Flame Retardant Fabrics

Flame retardant fabrics are engineered to resist ignition, prevent flame spread, and self-extinguish when exposed to high heat or open flames. This critical safety feature provides valuable escape time in emergency situations and is achieved through either inherent flame retardant fibers or specialized chemical treatments.

Examples include acrylic inherent flame retardant knitted fabric which offers permanent fire resistance without additional chemical treatments. This type of fabric is particularly valuable for welding, oil, and gas industries where exposure to high temperatures and flames is a constant risk .

2. Antistatic Fabrics

Antistatic fabrics are designed to prevent the buildup of static electricity, which can be crucial in environments containing flammable materials or sensitive electronic equipment. These fabrics typically incorporate conductive fibers such as carbon fiber to dissipate static electricity safely.

The integration of conductive materials creates a pathway for static charges to disperse rather than accumulate, significantly reducing the risk of sparks that could ignite flammable substances or damage sensitive electronic components .

3. Combined Protection Fabrics

Many industrial environments require protection from multiple hazards, leading to the development of fabrics that combine various functional properties. A prime example is the flame retardant and antistatic knitted fabric that incorporates both safety features in a single material.

This combination fabric typically consists of 100% polyester with conductive carbon fiber, offering long-lasting flame retardant and anti-static properties along with excellent moisture absorption, breathability, and wear resistance. The inclusion of bright fluorescent colors further enhances safety through improved visibility in low-light conditions .

The Technology Behind Functional Fabrics

The performance of functional fabrics stems from advanced textile technologies:

Fiber Engineering: Modifying the chemical structure of fibers at the molecular level to impart permanent functional properties

Surface Modifications: Applying specialized coatings or treatments to enhance fabric performance

Composite Structures: Combining different yarns and materials to achieve multiple functionalities

Nanotechnology: Incorporating nano-sized particles for enhanced protection without compromising comfort

These technological approaches allow modern functional fabrics to balance protection with comfort, addressing historical trade-offs between safety and wearability.

Sustainability in Functional Fabric Manufacturing

As the textile industry evolves, environmental responsibility has become increasingly important. The concept of green supply chains is emerging as a crucial approach for coordinated carbon reduction and pollution control in industrial sectors .

Modern manufacturers are adopting more sustainable practices, including:

Implementing environmentally conscious production processes

Reducing water and energy consumption

Utilizing recycled materials where possible

Ensuring compliance with international environmental standards

Conclusion: The Future of Functional Fabrics

The evolution of functional fabrics continues as technology advances, with smarter textiles incorporating sensing capabilities and adaptive properties entering the market. The integration of flame retardant and antistatic properties with other functional enhancements represents the cutting edge of protective textiles.

As a manufacturing-focused factory, CJTI stands at the forefront of this evolution, combining technical expertise with sustainable practices. Our commitment to environmental responsibility is matched only by our dedication to producing high-quality functional fabrics that meet diverse industrial needs. With decades of experience and numerous patents in functional fabrics, CJTI has established itself as a comprehensive solutions provider in the textile industry, offering expertise in flame retardant, antistatic, and other specialized fabrics for various applications .